Master data in SAP MM is the building block of all the logistics processes. It not only affects MM processes but also PM, QM, SD, FICO, PS and EHS module business processes. There are ten key master data in SAP MM. Please go through the list of master data in SAP MM and enhance your knowledge.

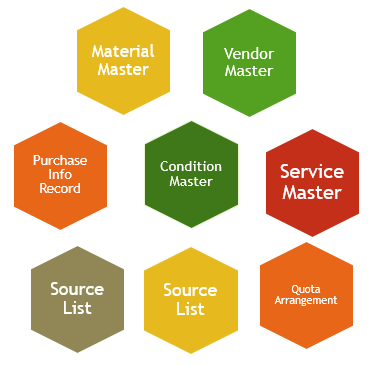

List of master data in SAP MM

Master data in SAP MM are necessary for all the MM and other module’s business processes. There are ten important master data in SAP MM. All the Logistics modules uses Material master therefore its quality must be good.

- Material Master (“Product master” in S4 HANA)

- Vendor Master (Business Partner)

- Service Master

- Purchase Info Record

- Condition Master

- Source List

- Quota Arrangement

- Class

- Characteristics

- Characteric values

Consulting Tips and recommendations

In a full life cycle implementation project master data plays a critical role. Poor designing of master data and its nomenclature can totally ruin the show. If you load garbage in system, system will throw garbage. You must take care of following tips while designing master data with business:

- Material Master designing is a joint activity between MM, SD, QM, FICO, PP, PM and EHS.

- Business Partner is introduced in SAP S4 HANA. It represents vendor master data. Vendor master design is a joint activity between MM and FI.

- Nomenclature of Material Master, Service Master and Vendor master id and their description should be finalized as per a predefined formulae. This is known as Cataloguing.

- For ex: First 2 characters of material master should indicate material type such as Raw material, spare part or semi finished material. The next character can indicate its Function. Such as it is Air Circuit Breaker, Pump, Shocker, etc. Similarly you can decide the nomenclature of vendor master and service master. But you must do thorough study of master data before giving any recommendation. As per scope of project this activity can be done by client. You can only give consultation by showing examples.

- Recommend client to develop a Material Cataloguing tools for generating material number. This Cataloguing helps business to identify and locate the material, vendor etc easily in SAP.

- Finalize the Material type at the beginning of the blue print phase. So that purpose of each material type is clear to client. This will help them to prepare material master data in a correct form. Many times its has been observed that client gets confused between different material types.

- Procedure to create the master data post go live must be defined during implementation itself. Responsible person at client side must be identified and all templates must be in place.

- Do not forget to ask for material or vendor description in client local language.

- For ex: If you are working for a German client then client may ask to enable master data uploading program to handle multiple languages such as German, Dutch etc.

- Unit of measurement in material master is very critical. Generally people ignore it and later on it creates isue while doing business. Lot of SAP MM support tickets are created due to incorrect unit of measurement. You can use the additional data in material master.

Master Data Dependency

Here is the list of master data in sap mm with the dependency of other data which must be created before we upload SAP MM related master data. Please refer below table to understand the dependency:

| S. No. | Master data in SAP MM | Dependency on other master data |

|---|---|---|

| 1 | Characterisitcs | Unit of Measurement (UoM) |

| 2 | Class | Characteristics |

| 3 | Business Partner (Vendor or Supplier) | GL Account |

| 4 | Material Master | Profit Center, UoM, |

| 5 | Service Master | |

| 6 | Purchase Info Record | Material master, Vendor (Supplier) |

| 7 | Condition Master | Material master, Vendor, |

| 8 | Source List | Purchase Info Record, Material, Vendor |

| 9 | Quota Arrangement | Purchase Info Record, Material, Vendor |

| 10 | Characterisitc values | Class, Characterisitcs, Material Master. It depends upon where we are assigning the characterisitc values. |

SAP MM Master data uploading

SAP MM Master data upload needs a proper strategy. You cannot plan it in a hustle. There are few ways we can do so. Please refer below table to understand various ways to upload MM master data. I have included only those ways which can be used by a functional consultant.

| S. No. | List of master data in SAP MM | Master data upload approach/ tool |

|---|---|---|

| 1 | Material Master (or Product Master) | Migration cockpit LSMW MM17 SAP Data Service |

| 2 | Business Partner (Vendor Master) | Migration cockpit SAP Data Service |

| 3 | Purchase Info Record | Migration cockpit SAP Data Service |

| 4 | Source List | Migration cockpit SAP Data Service |

| 5 | Quota Arrangement | Migration cockpit SAP Data Service |

| 6 | Service master | LSMW BDC SAP Data Service |

| 7 | Condition Master | LSMW Migration cockpit SAP Data Service |

| 8 | Class | LSMW Migration cockpit SAP Data Service |

| 9 | Characterisitcs | LSMW Migration cockpit SAP Data Service |

| 10 | Characteristc values | Migration cockpit SAP Data Service |