Introduction

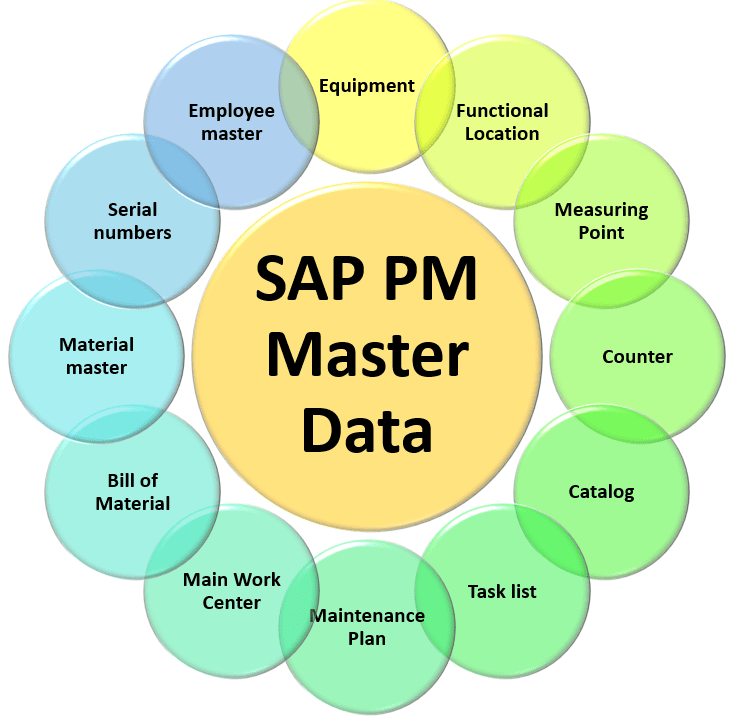

Master data in SAP PM is the highest in count than any other module. Master data makes the life of an end user easy. Certainly it can full fill all maintenance business processes needs. Significantly there are nineteen master data objects in PM module. Each has its own benefit and importance. You can click on each of them to know the details.

SAP PM Master Data list

- Equipment

- Functional Location

- Class

- Characteristics

- Characteristic values

- Maintenance Plan

- Single Cycle Plan

- Strategy Plan

- Multiple Counter Plan

- Task List

- Catalog

- Bill of material

- Construction Type (Material BoM)

- Equipment Bill of Material

- Functional Location Bill of material

- Main Work Center

- Main work center hierarchy (Used rarely)

- Measuring Points

- Counters

- Permits

- Material master (Material type ERSA and NLAG)

- Serial number

- Master Inspection characteristics (MIC)

- Maintenance Strategy

- Cycle sets

Consulting Tips (Things to remember)

During design phase you must remember following points:

Dependency of master data on each other must be explained to client.

- Bill of material cannot be created without material master.

- Measuring points and counter has dependency on equipment, functional location and characteristics.

- Serial number has dependency on material master and equipment.

- Equipment and functional location has dependency on Main work center

- Always explain the difference between equipment and functional location to business.

- Compare the use of equipment and functional location from business point of view.

- Clarify the importance of number range of equipment (external and internal).

- Give demo of measuring points and counter. Tell business about the warning and error message when a reading goes beyond permissible limit.

- Use of construction type in maintenance order processing is equally important.

- Another key point is demo of permits and its control on maintenance order processing.

- Explain how class and characteristics can show the specifications of machinery.

- Catalog code and catalog profile in sap pm can do wonders in notification processing. Therefore, give a notification processing demo and related reports.

- Material master needs coordination with MM and FICO modules. Target to finish it at early stage.

- Maintenance plan category can control triggering of maintenance call object. This must be explain and finalized in design phase.

- Task list needs a well structure program to upload. There is a possibility that business wants to upload long text also. So it is better to identify such thing early. Plan tasks for ABAP programmer in advance.

- Not to mention that serial number is mainly used in refurbishment process.

- Master inspection characteristics are assigned to task list operations and used in Calibration process

SAP PM Master Data dependency

| S. No. | Master Data in SAP PM | Dependency on other Master Data |

| 1 | Catalog | No dependency, It can be moved with TR movement |

| 2 | Permit | No dependency, It is assigned to equipment of functional location |

| 3 | Characteristics | Unit of measurement (if the UoM is not available in standard SAP) |

| 4 | Class | Characteristics |

| 5 | Maintenance Strategy | No dependency |

| 6 | Cycle Set | No dependency |

| 7 | Work Center Hierarchy | No dependency |

| 8 | Main Work Center | Cost Center, Activity type, Production Supply area, Employee master (HR), Work Center Hierarchy |

| 9 | Material Master | Cost center, Profit center, UoM, |

| 10 | Material BoM | Material Master |

| 11 | Functional Location | Main work center, Cost center, class, characteristics, asset master, MBoM can be used as construction type, permits can be assigned to FLoc |

| 12 | Equipment | Functional Location, Main work center, Cost center, class, characteristics, asset master, MBoM can be used as construction type, permits can be assigned to Equipment, Asset master (FI) |

| 13 | Measuring Point | Equipment, Functional Location, Characteristics, Catalog code groups and codes |

| 14 | Counter | Equipment, Functional Location, Characteristics, Catalog code groups and codes |

| 15 | Serial Number | Material Master, Equipment |

| 16 | Functional Location BoM | Functional Location, material master |

| 17 | Equipment BoM | Equipment, material master |

| 18 | General Task List | Main work center, Maintenance strategy, material master, activity type |

| 19 | Equipment Task List | Equipment, Main work center, Maintenance strategy, material master, activity type |

| 20 | Functional Location Task List | Functional Location, Main Work Center, Maintenance Strategy, material master, activity type |

| 21 | Single Cycle Plan | Task List, Equipment, Functional Location, Counter |

| 22 | Strategy Maintenance Plan | Task List, Equipment, Functional Location, Counter, Maintenance Strategy |

| 23 | Multiple Counter Plan | Task List, Equipment, Functional Location, Counter, Cycle set |

| 24 | Characteristic values | All class, charactertistics, respective master data object |

SAP PM Master data uploading methods

SAP PM master data can be uploaded with different ways suchas LSMW, Migration cockpit, Program. Separate program is required when you want to upload long text. Although there are option available in migration cockpit to upload long text also. Depending upon the situation you need to take the decision on program.

| S. No. | Master data | Master data uploading approch/ tool |

|---|---|---|

| 1 | Catalog | LSMW Migration cockpit |

| 2 | Permit | LSMW |

| 3 | Characteristics | LSMW Migration cockpit SAP Data Services (BOBJ) |

| 4 | Class | LSMW Migration cockpit SAP Data Services (BOBJ) |

| 5 | Maintenance Strategy | Migration cockpit |

| 6 | Cycle Set | Migration cockpit |

| 7 | Main Work Center | Migration Cockpit SAP Data Services (BOBJ) |

| 8 | Material Master | LSMW Migration Cockpit MM17 SAP Data Services (BOBJ) |

| 9 | Material BoM | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 10 | Functional Location | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 11 | Equipment | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 12 | Measuring Point | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 13 | Counter | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 14 | Serial numbers | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 15 | Functional Location BoM | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 16 | Equipment BoM | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 17 | General Task List | LSMW Migration Cockpit Custom Program (depends on complexity) SAP Data Services (BOBJ) |

| 18 | Functional Location Task List | LSMW Migration Cockpit Custom Program (depends on complexity) SAP Data Services (BOBJ) |

| 19 | Equipment Task List | LSMW Migration Cockpit Custom Program (depends on complexity) SAP Data Services (BOBJ) |

| 20 | Single Cycle Plan | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 21 | Maint Strategy Plan | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 22 | Multiple Counter Plan | LSMW Migration Cockpit SAP Data Services (BOBJ) |

| 23 | Characterisitcs values | LSMW Migration Cockpit SAP Data Services (BOBJ) |