SAP PM is a niche module among all other SAP modules. For a bright career in SAP PM module you need deep understanding of maintenance processes, reports, KPIs, maintenance history and costing. To know the maintenance processes there is no book available in market therefore it is difficult to build knowledge in maintenance processes.

In this blog post i have created more than 100 SAP PM questions and answers to help consultants and learners to enhance their business knowledge and important SAP PM features. These questions and answers will not only help them to prepare for interviews but also to face client in implementation projects.

Table of content

Organization Structure in SAP PM (15 Interview Questions)

1. What is Maintenance Plant?

Ans. Maintenance Plant is the place where all the technical objects (Plant and machinery) are physically installed. In SAP it is a 4 digit alphanumeric key.

2. How do you create a maintenance plant?

Ans. We do not create a maintenance plant in system. When plant is created in configuration by SAP MM consultant automatically a logical maintenance plant gets created in PM module. There is no separate node in SPRO to create Maintenance Plant.

3. What is a planning plant?

Ans. Planning plant is the place where all the maintenance planning activities are carried out. In SAP it is a 4 digit alphanumeric key. Planning plant is assigned to maintenance plant as per the type of planning.

4. What is a planner group?

Ans. Planner group is the group of people or individuals who does maintenance planning in a planning plant. It is created and assigned to a planning plant. It is a 3 digit alphanumeric key.

For example:

Planner group can be created according to different departments:

- ELE – Electrical

- MEC – Mechanical

- CVL – Civil

- INS – Instrumentation

Planner group can also be created as per shift because many times activities are planned for each shift:

- SHA – A shift PG

- SHB – B Shift PG

- SHC – C Shift PG

There are lot of standard SAP Reports which can help tracking maintenance activities, history and cost at planner group level.

You can also recommend 001, 002 and so on…as planner group to your client because in that case you can extend planner group upto 999. But normally client does not like numbers in planner group because end user is comfortable with alphabets.

5. What is main work center?

Ans. Main work center is group of people who does maintenance execution in the field. For example Electrician, Welder, Fitter, Technician. It is an eight digit alphanumeric key.

Examples of main work center:

- ELEC0001 – Electrical

- MECH0001 – Mechanical

- MECWRK01 – Mechanical Workshop

- ELEWRK01 – Electrical Workshop

- CIVIL001 – Civil

It is recommended to put numbers into work center nomenclature because in that case you can extend the work center upto 99 or 999.

We can assign employee ids to a main work center under the capacity tab.

6. Which Work Center Category is used in plant maintenance work center? What is controlled by work center category?

Ans. Work center category used by PM module is “0005”.

Work center category can help in following ways:

- Making a specific field mandatory or hide or grey

- The various tabs in work center screen are controlled by work center category

- Work center default values can be configured in SPRO

7. What is the purpose of having cost center in Main Work Center? How it is different from the cost center in equipment and functional location master?

Ans. Here you go:

- Cost center in main work center is responsible to carry out the maintenance work. It supplies (not receive) the cost for implementing the maintenance work. However, cost center in equipment and functional location master is the cost receiver (not supplier). It is the maintenance requesting cost center.

- In maintenance order you will find that Cost center from main work center copy into Additional Data tab as Responsible cost center. On the other hand the cost center from equipment master and functional location master copy into the account assignment under location tab and the same copy into the settlement rule because it is the cost receiver.

- Therefore id of both cost centers can be different from each other and their purpose is different in maintenance processing.

8. What is plant section?

Ans. Plant section is used to subdivide the maintenance plant from the point of view of production responsibility. The person responsible for the plant section is the contact for coordination between production and plant maintenance.

The plant section can be used in reports.

In different types of industries it is used to manifest the section id and description because most of the clients do not want to display the name of responsible production in charge of that section.

It is a three digit alphanumeric key. It is created and assigned to a maintenance plant.

Few examples of plant section:

- A01 – Area 1

- A02 – Area 2

- PL1 – Production line no 1

- PL2 – Production line no 2

9. What is the difference between maintenance plant and planning plant?

Ans. Maintenance plant is the place where all machinery is physically installed. This machinery undergo maintenance periodically.

On the other hand, Planning plant is the place where we do the maintenance planning of the machinery (technical object) which is installed in maintenance plant.

10. What are different types of planning can be done in SAP PM module?

Ans. In SAP PM we can have three types of planning:

- Centralized Planning

- Localized Planning

- Partially Centralized/ Localized Planning

You can read more details here. Read more.

11. What is the purpose of maintaining Cost Center in main work center cost center tab?

Ans. Cost center maintained in costing tab of a main work center is the requesting cost center. The cost center which is requesting to do some work in field. The cost center which is supplying money to execute certain task in the field. The cost center maintained in settlement rule of a maintenance order is the receiving cost center. Do not confuse between these two cost centers.

12. What is work center hierarchy?

Ans. Work center hierarchy can be created by using t code CR22. It represents the maintenance organization hierarchy. For example: Welder, Fitter, Plumber reports to a supervisor and all has different work centers. Then we will create a work center hierarchy and assign Supervisor at top lelve and Welder, Fitter and Plumber below it. This feature helps to determine the organization elements while assigning the maintenance order or notifications to an employee with certain designation in custom fiori applications.

13. What is the purpose of assigning Activity type in main work center costing tab?

Ans. Purpose is to bring activity type into internal manpower cost calculation. Actiivty type is created by CO consultant after detailed discussion with client’s finance department. Activity type contains the hourly rates defined for internal man power. It is created in t code KP26 or Fiori app Manage Activity type. It is created with reference to cost center.

Step 1: When we assign a cost center in the costing tab of a main work center the activity type can also be assigned there.

Step 2: We create a maintenance order and enter the main work center in the order operation, the activity type automatically gets copied into the operation.

Step 3: In next step we enter the number of internal person (such as technician, welder, fitter etc.) working on that operation and duration for which they will work.

Step 4: This helps in calculating the planned cost of internal labour in a maintenance order

Step 5: When user post the confirmation the actual internal man power cost is calculated by multiplying -> Duration x No. of Person x Rate. This rate comes from activty type which is assigned to the main work center

Note: Do not forget to maintain the formule under the costing tab otherwise cost will not be calculated.

14. Where do you assign activity type in master data?

Ans. We assign Activity type in Cost Center. Cost center is assigned to Main Work Center in Costing tab. In main work center the activity type can be assigned. From main work center it automatically copy to maintenance order. Activity type is assigned to cost center under tcoe KP26. It is responsibility of CO consultant to do this assignment but you should know this tcode and its usage.

15. There is a main work center which is no longer required. You do not want that work center to appear in the system. Which feature in SAP will you use to handle this situation?

Ans. There are two ways to handle such situation.

- Way 1 => You can lock the work center. This will show an error message if end user try to use the work center in any maintenance related transaction. To lock the work center go to the main screen of work center and click on the top menu bar -> Extra -> Status -> Lock/ Unlock. After locking the work center it can be unlock if you wants to use it again and also the work center will appear in the drop down list of work centers.

- Way 2 => If you want to permanently remove a wrk center from system and you are fine if it does not appear in the drop down list then you can recommend to delete the work center. The path is Extra -> Status -> Delete flag. If you want the work center again in system after deletion then you need to create it again.

Master Data in SAP PM (40 Interview Questions)

Here is the list of SAP PM Interview questions and answers on Master Data. It includes questions on master data screens, configuration, Fiori apps and many more. This section is further divided into different sub-sections to display questions on specific master data. For example: There is a separate section for Equipment, Functional Location, measuring points etc. There is also a separate section for general questions on SAP PM master data.

This section contain general questions on SAP PM Master data. These questions are applicable to all PM Master data objects.

1. What are the important master data in SAP PM?

Ans. Here is the list of master data in SAP PM.

2. In what sequence you upload SAP PM Master data in a project?

Ans. This answer will help you to face job interviews and also strengthen you while facing client in a implementation or data migration project.

Here is the sequecne and dependency of master data in SAP PM

- Catalog code groups and codes: It is moved to production system along with transport requests during cutover. So it is the first master data which gets moved into production system in a implementation and data migration project.

- Public Cloud: If you are working on a Public Cloud system then there is no Transport request required to move catalog code groups and codes to production system. There is a Fiori tile used to add catalog code groups and codes. So this master data can be be moved later on also and it has no dependency on any other master data for public cloud system.

- Permits: Permits are not dependent on any other mater data. We can load them at this point. Later on it can be assigned to equipment or functional location.

- Characteristics: Characteristics can be moved next. It has dependency only on transport request. In transport request we can move charactristic groups and unit of measurement.

- Class: Class is dependent on characteritics because we have to assign characteristics to a class. It has dependency on characterisics. Although system will not stop you to create a class before but its better to create it after characteristics. It has a dependency on transport request if you want to configure class group.

- Maintenance Strategy: It is not dependent on any other master data object. Maintenance strategy is used while creating task list. It is entered in task list header. But it is applicable only if you are using maintenance strategy plan.

- Cycle sets: Cycle set can be create along with maintenance strategy. It is not dependent on any other object. it is used in Multiple counter plan.

- Work Center Hierarchy: Work center hierarchy is not used in every project but very few. If it is a part of project then it has to be created before we create maintenancd work center.

- Maintenance Work Center: Maintenance work center has a dependency on cost center, activity type, supply area and HR master (employee ids). It can be assigned to a work center hierarchy if applicable.

- Functional Location: Functional Location can be created because main work center, class and characterisitcs are already created. In other modules cost center, asset master need be created.

- Material Master: Material master (Material type: ERSA) can be created before equipment master if we want to create material BoM and assign it to equipment as construction type in Structure tab.

- Material BoM (Construction type): Material BoM is dependent on material master (Material type: ERSA). It is used as construction type in equipment master therefore it should be created before equipment master.

- Equipment: Equipment needs functiomal location and main work center. Many time we assign class and characterisics also to an equipment. It also needs cost center and asset master.

- Serial Number: We can create serial number. It is dependent on material master and equipment master and both are ready.

- Measuring Point: Measuring point is dependent on functional locstion, equipment, characteritics and catalog code group.

- Counters: Counter has dependency same as measuring points.

- Functional Location BoM: We have functional location in place and material master also uploaded then why to wait for functional location BoM. Upload it.

- Equipment BoM: We have equipment master and material master loaded then we can go for equipment BoM.

- Task List: All types of Task lists can be created now. We have main work center, equipment, functional location, material, activity type in place. so we can proceed with TL.

- Maintenance Plan: We can create any type of maintenance plan. It is dependent on Task list, equipment, functional location, counter, maintenance strategy and cycle set.

3. What is concept of equipment numbering?

Ans. Equipment can have internal and external numbering. Generally client opt for external numbering because they want to have the equipment number as per the plant engineering drawing. Their Supervisor and technicians are familier with it.

On the other hand internal numbering is helpful when user wants to track maintenance history and cost even if the equipment is removed from Functional location to another.

4. Is it possible to change the equipment category once created?

Ans. Yes, it is possible to change the equipment category of an equipment. Please refer below screenshot. Please go to t code IE02, then go to top menu bar and click on Edit and then click on Change category (as shown in below screen shot). There is a criteria which must be fullfilled to change the category.

5. What is the criteria to change the equipment category?

Ans. There are four important criteria to change equipment category.

- First one is that both categories must have same reference category type in SPRO

- User status profile assigned in SPRO should be same for both categories

Special note: There are other fields such as Partner function, object info and view profile which can be different for new and old categories. System will only issue a warning message and allow to change the equipment category. There cold be an inconsistency in results but system will allow the change in category.

Please refer below screenshot for details:

6. Under what business situation you need to change the equipment category of an equipment?

Ans. Sometime after go live of a project end user or master data team creates a new equipment. To create the equipment they run the tcode IE01. On the IE01 initial screen equipment category ‘M’ appears by default. A new person generally does not pay attention on the default equipment category and press enter and go to the main screen and does the data entry and saves the equipment. Now suppose user wanted to create the equipment with category ‘S’ or ‘Q’ then he/she will come up with a requirement to change the equipment category.

7. Why cost center field is important in equipment master?

Ans. Cost Center field is important in equipment master because at the time of creating the maintenance order with reference to equipment it automatically copies to the maintenance order “Location” tab under account assignment sub-screen and then it automatically populated in the settlement profile depending upon the SPRO settings in settlement profile. It is important for Breakdown, Corrective, Preventive, Calibration and predictive Maintenance because in these processes the maintenance cost is settled on cost center.

8. Why do you need an equipment and functional location both?

Ans. This question can be asked by your client because they have to prepare lot of master data and they want to know why to prepare two master data when we can use any one of them i.e. either equipment or functional location.

So here are the reasons:

- Serial numbers: Equipment can have serial numbers but a functional location cannot have serial number.

- Levels in tech system: Functional location can divide the entire factory layout in the form of different levels so that at each level we can fetch maintenance history and maintenance cost reports.

- Equipment Usage: We can move an equipment from one functional location to another and track it usage. “Tracking usage” means all the measuring points readings, the duration it was installed at a certain location, number of notifications, maintenance cost etc. Such thing is not possible in functional location.

- Nature of maintenance work: Sometime maintenance department does painting work or construction work on particular structure in plant area. Such kind of work can be recorded by creating maintenance notification or order with reference to a functional location.

9. What is the purpose of authorization object in equipment and functional location?

Ans. Sometimes different departments does not want their technical objects to be edited or visible to other departments. In such a business situation an SAP Consultant can recommend to use the field authorization object. It can be configured in SPRO as a four digit alphanumeric key. Once the authorization object is created you can ask the security consultant to link the authorization object to the role and then to the user id. So that when the user logs in he/she will have access to only those technical objects where the authorization key is assigned.

10. What is purpose of Technical ID field in equipment master data?

Ans. Technical id field should have the technical id of equipment according to engineering drawing. For example: There is an equipment 10002745, now operations and maintenance department can not find out this id in engineering drawing. Therefore, therefore, there should be some field in master data where we can maintain technical id.

11. What is asset viewer in SAP PM ?

Ans. Asset viewer is a Web dynpro based Fiori Application launch by SAP in S4 HANA. This is a very versatile Fiori App. It can show you complete details fo the technical object such as Functional location, equipment, measuring points, all task lists, all maintenance items/ plans created, notifications and orders created, picture of the technical object and complete technical object hierarchy. You must recommend this Fiori app to your client because it is a single point of all information about technical object.

12. What are the standard SAP tools available to upload SAP PM master data in SAP S4 HANA?

Ans. Following standard SAP tools can be used to upload SAP PM master data in SAP S4 HANA:

- LTMC – Landscape Transformation Migration Cockpit (tcode is obsolete) in latest version of S4 HANA. we can use the migration cockpit through a Fiori App. Rest of the functionalities are same.

- LSMW – Legacy System Migration Workbench

13. What is purpose of construction type in equipment master?

Ans. Please read my article on construction type. [Read more]

14. Why Manufacturer field is important in equipment master and functional location master?

Ans. “Manufacturer” is used in reports such as MCI2, IE05, IH06. By using these reports we can analyze which Manufacturer machinery is undergoing a high maintenance most. We can also analyze which Manufacturer machinery is taking maximum efforts in maintenance, undergoing maximum breakdowns and has high cost of maintenance. Therefore, business can take important decisions while making future purchase of plant machinery from that manufacturer.

For better reporting we should maintain a value in this field in equipment master.

15. What is a maintenance work center in SAP PM? What is its use in maintenance business?

Ans. Main Work center represents the group of people or individual who are responsible for execution of maintenance work in the maintenance plant area (or field). Generally all the technicians, mechanic, fitter, welder, crain operator, electrician, inspector etc are considered as a main work center.

It is used in maintenance business when we create a maintenance notification or order. We assign it to an order so that business knows who is responsible for the execution of maintenance work.

16. Is it possible to maintain the shiftwise manpower in main work center?

Ans. Yes, it is possible to maintain the shiftwise timings, working days, count of manpower working. Please read this article here.

17. Can you use call horizon and shift factors in multiple counter plan?

Ans. No, there is no such option. Call horizon and shift factors are assigned in Single Cycle Plan and Maintenance strategy plan not in Multiple Counter plan.

18. What is object information key in SAP PM?

Ans. Object information key, a special information window, pops up while creating maintenance notification. It contains a brief historical information about the technical object.

19. What is t code for deadline monitoring?

Ans. IP30 for deadline monitoring and IP30H for mass scheduling of maintenance plans.

20. What is the t code to create new catalog code groups and codes with description?

Ans. QS41. Please note that this t code is available on easy access screen but it requires a transport request movement.

21. Is it possible to schedule an individual plan? What is the t code?

Ans. Yes, it is possible to schedule an individual plan. You may use t code IP10.

22. What is Measuring Point Entry List (tcode IK31)? What is its purpose?

Ans. Suppose there are several measuring points in a plant. Maintenance department takes readings of 50 different measuring points on daily basis and readings of 100 measuring points on weekly basis. Now maintenance department wants to have a two separate collective lists of daily readings and weekly readings. So, they will create two different lists with two different names (For ex: Daily_Readings and Weekly_Readings) using t code IK31. These are knowns as measuring point entry lists. In this way maintenance department does not miss any daily and weekly reading. Once measuring point entry list is created then user can enter the readings collectively in IK34 and create measurement documents collectively.

It makes the life easy for the person who is taking reading on daily and weekly basis for different technical objects.

User is not required to search the daily and weekly measuring points from the ocean of thousands of measuring points.

It is important to note that we can have measuring points from different plants in one measuring entry list. Which means that this feature is independent of plant.

23. What is difference between system status and user status?

Ans. Difference between system status and user status as follows:

- System status is an Standard SAP element which set internally by SAP when we post certain transaction in SAP. However, user status is a configurable element which can be configure in SPRO to make certain transaction more informative and systematic.

- User status can control certain business transactions allowed by system status. For ex: We can Stop the system status notification completion (NOCO) unless a user status (PRCN – Production Confirmation) is not set.

- We assign all user status to a status profile and assign that status profile to notification type or order type or equipment category etc. This gives a flexibility to use different user status with different notification types but we do not have such flexibility with system status.

Important Concepts on User Status

- We can set more then one user status at a time if we do not put a number with it in SPRO.

- We can assign an authorization key to each user status and link this key with the user id so that only authorized person with authorized key can set that user status.

- We can assign user status to following object types in PM module: Equipment, functional location, maintenance notification, maintenance order, maintenance plan, tasks in notification, PM operations.

24. Is it possible to create and schedule a maintenance plan without task list?

Ans. Yes, it is possible to create a maintenance plan without task list but we cannot create a maintenance strategy plan with out task list because maintenance cycle (maintenance package) is adapted from task list and without maintenance cycle we cannot create a maintenance plan.

We can create a Single cycle plan and Multiple counter plan without task list but not Maintenance strategy plan.

25. Which material type is used for maintenance spare parts?

Ans. For spare parts (Stock able) material type is ERSA and for non stock items material type is NLAG. Sometime UNBW material type is also used to manage unvaluated special tools.

26. Can we assign more than one maintenance item to a maintenance plan?

Ans. Yes, we can assign more than one maintenance item to a maintenance plan. There could be a business situation when we need one maintenance cycle and start date for two technical objects. We can use this feature in such time.

For example: A motor and pump can undergo maintenance at the same time. If a motor is under preventive maintenance then pump will also be down because motor drives the pump. So it is better to take their annual maintenance at the same time by assigning them in maintenance items on same maintenance plan. There will be same maintenance cycle and same start date. This will result into triggering two maintenance order at the same time. One for motor and one for pump.

If we create different plans with different dates then it may create orders with different dates and this will increase technical object down time.

27. Can we assign one maintenance item to more than one maintenance plan?

Ans. No, it is not possible to assign one maintenance item to two different plans.

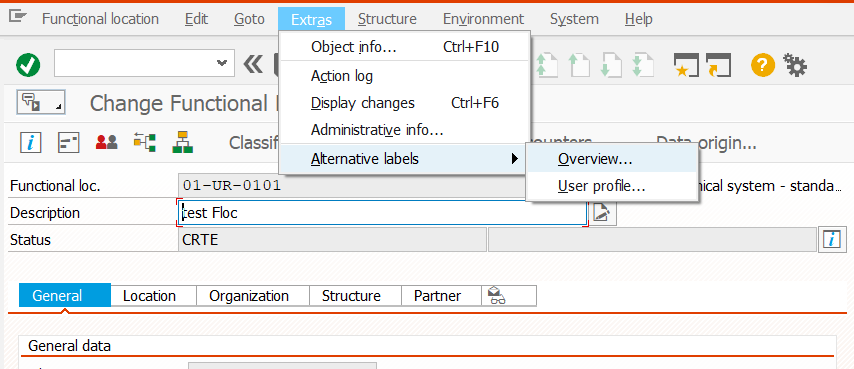

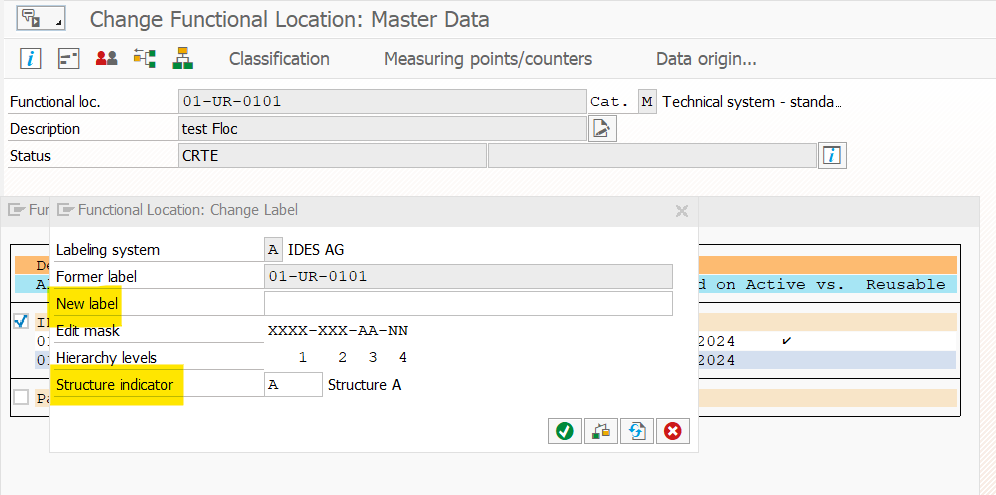

28. Is it possible to change the structure indicator and label of functional location?

Ans. Yes it is possible. But we will have to activate alternative labeling for that. It is not recommended at all. Please refer below screen for details.

29. What is the business purpose of field authorization group in equipment master and functional location master?

Ans. In the equipment master and functional master we have the field authorization object. This field allows to put restriction to end user to display and change the technical object on the basis of authorization group. Authorization group can be configured in SPRO and assigned here. Afterwards we can link the authorization group with the user id whom we want to authorized to access that technical object.

Many times Electrical department does not want Mechanical department to view and change their equipment and vice-versa. In such a business situation we can use Authorization group.

30. What are the equipment categories available in standard SAP?

Ans. In standard SAP following equipment categories are available:

- M – Machines – This category is used for all machines in a plant area. Most widely used in SAP projects.

- K – Vehicles – This category is used for all vehicles such as fork lists, cranes, cars, jeeps etc

- L – Linear assets – This category is used for linear assets such as railway line, pipe line, transmission line, optical fibre etc. We have to activate business functions to activate this category.

- P – Production Resource/Tools – This category is used to create special tools used in production and maintenance such as vibration meter, ELCB tester, thermal imaging camera etc.

- Q – Test/ measurement equipment – This category is used mainly for laboratory machines or workshop machines which are used for calibration of measuring devices.

- S – Customer equipment – This category is used for the machines supplied to customers and we want to maintain their warranty data, customer details and maintenance history in our system. It is mainly used in CS module.

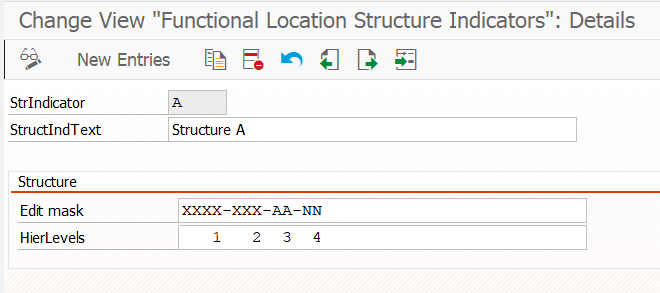

31. What is structure indicator in SAP PM?

Ans. Structure indicator specifies the typical structure to represent functional location label. Structure indicator includes description (max. limit 40 Char), edit mask, hierarchy levels.

Functional location structure indicator represents the skeleton of complete technical structure of a manufacturing unit.

32. What is edit mask in a structure indicator?

Ans. Edit mask is a part of structure indicator in configuration. It represents the format or syntax of functional location structure label. Generally each block of edit mask is separated by a hyphen (-). But we can also use ‘/’, Blank, . dot, _ underscore, = equal, + plus, ; semicolon, : colon.

We can use folowing signs to create edit mask.

| Sign | Meaning of sign |

|---|---|

| A | Only alphabets |

| N | Only numbers |

| X | both numbers and alphabets can be entered |

| S | Special characters -> & ( ) + , . / : ; < = > |

33. Can we change edit mask after go live?

Ans. This question can be asked by your client during an implementation project while gathering configuration data. Initially even client is not confident that if the edit mask (structure indicator) they finalized will work in every location of manufacturing plant for future requirements. So answer is Yes,. Yes, it is possible to change the edit mask signs and hierarchy levels. But it is not advisable to do . When you try to make changes in the configuration you will get a warning message -> “Structure indicator already being used”. But you can bypass this message and change the edit mask.

You can also add more hierarchy levels in edit mask. System will not stop you. But be carefull and do the impact analysis in Sandbox by creating new master data, notificaion and orders and see the standard and Z reports.

34. Under the CAPEx project a new section has been commissioned in a manufacturing unit. Now this new section has resulted into addition of a new hierarchy level in the functional location. But in the structure indicator is already at the last level in functional locatioin label. What will you do in such situation?

Ans. We can add another hierarchy level in the edit mask of structure indicator and add new functional location label in the master data and start creating notifications and order.

35. In an implementation project sonetimes client side remain in fix while finalizaing the structure indicator for a manufacturing plant. What will be your recommendation to client which can help them to finalize the structure indicator?

Ans. In such situation you can recommend the client to see the engineering drawing of the complete factory layout which has every location in it. This drawing can help client to finalize the structure indicator. Even if client observes that one structure indicator will not work for plant then go for “XXXXXXXXXXXXXXXXXXXXXXXXXXX and so on”.

36. You have created a structure indicator upto 40 characterisctics but when you go and create a functional location the system does not allow you to go beyond 30 char. When you check the details of field in config and gui you find that it has 40 char. What will you do to accommodate 40 char in functional location label?

Ans. You can activate alternative labeling to accommodate 40 characters in functional location label. But it will later create issues while uploading equipment master for functional location. Therefore test it properly.

37. Suppose you are writing a functional specification. You have to write the logic to fetch all equipments which are installed to a certain functional location? What will be your approach?

Ans. There three ways to do so:

- Using Functional Module : there are two function modules which can help you to fetch the equipments installed to a functional location.

- EQUIPMENT_INSTALLED: You can use SE37 tcode and give input of Functional Location. After executing the FM you will get the list of equipments installed on the functional location.

- ALM_ME_FUNCLOC_INSTALLED_EQUI: You can use SE37 tcode and give input of Functional Location. After executing the FM you will get the list of equipments installed on the functional location.

- SAP Tables linking: Pass the functional location (TPLNR) in the table ILOA and fetch the value of ILOAN. Copy all the values of ILOAN and pass them in table EQUZ with DATABI equals to 31.12.9999 (DD.MM.YYYY). This will give you the list of all equipments installed on the functional location.

38. Suppose you want to display the user status and system status description in a report or form for a notification? Then what will be the table logic?

Ans. Here is the logic to fetch user status and system status from notification:

User status logic

- Step 1: Pass the notification number in table QMEL and fetch the value of Object number (OBJNR).

- Step 2: Pass the OBJNR from step 1 and OBTYP = ‘QMI’ into table JSTO and fetch the value of STSMA (Status profile)

- Step 3: Pass the OBJNR from step 1 into table JEST and fetch the value of STAT which starts with ‘E*’. Field INACT=” ” (Blank) and choose the record with highest value of CHGNR.

- Step 4: Pass the value of STAT=ESTAT from step 3 into, STSMA from step 2 and SPRAS = ‘E’ into table TJ30T and fetch the value of TXT04 (Short Name) or TXT30 (User status description).

System Status logic

- Step 1: Pass the notification number in table QMEL and fetch the value of Object number (OBJNR).

- Step 2: Step 3: Pass the OBJNR from step 1 into table JEST and fetch the value of STAT which starts with ‘I*’. Field INACT=” ” (Blank) and choose the record with highest value of CHGNR.

- Step 4: Pass the value of STAT=ISTAT from step 2 into and SPRAS = ‘E’ into table TJ02T and fetch the value of TXT04 (Short Name) or TXT30 (System status description).

Note: To fetch the historical log of changes in user status and system status in notification or order or technical object we should use JCDS table.

39. What is the use of serial numbers ?

Ans. Serial numbers are used for tracking purpose. Remember the word tracking while answering this question.

- Serial number is used to establish a connection between an equipment in manufacturing area and material in warehouse.

- For maintenance department it is an equipment and for Warehouse people it is a material. Now it is the serial number which connects and equipment and material.

40. What is difference between Maintenance strategy plan and Multiple counter plan?

Ans. Here are the key difference between Maintenance strategy plan anf Multiple counter plan:

| S. No. | Maintenance Strategy Plan | Multiple counter plan |

|---|---|---|

| 1 | Every maintenance operation can have a different maintenanc cycle (maintenance package) | We cannot have different maintenance cycle for each operation |

| 2 | Strategy plan cannot be created without a task list | We can create a multiple counter plan without task list. |

| 3 | Maintenance strategy is used to maintain different maintenance cycles | Cycle set is used to maintain different time based and counter based cycles |

| 4 | Maintenance strategy is created using tcode IP11 | Cycle set is created using tcode IP11Z |

| 5 | We can use scheduling parameters such as call horizon, shift factor, tolerance, scheduling indicator | We can use different scheduling paramters such as Operation type AND OR logic. |

| 6 | Ex: We can trigger maintenance order with required operations as per pre-defined maintenance cycle. Suppose maintenance of a pump required 10 operations but only 2 operations are relavant for half yearly maintenance then we can trigger order with only those two operation on half yearly basis. | Ex: We can define two criterias of maintenance and trigger maintenance order if one or both criteria full the requirement. A pump need maintenance after every 3000 running hours or 6 months. In such as case multiple counter plan gives the freedom to choose Option 1: If we want to trigger order once 3000 running hours are completed or 6 months time duration is completed. Option 2: If we want to trigger order when both 3000 running hours and 6 months time duration is completed. |

| 7 | Tcode – IP42 | Tcode – IP43 |

Business Processes in SAP PM (15 Interview Questions)

1. What are the key business processes in SAP PM module?

Ans. There are 10 business processes in SAP PM.

2. In which business process you can use serial numbers?

Ans. Serial number is used mainly in Refurbishment process and scenario when we send a machine outside the plant for repairing.

3. Where does the cost of CAPEx order is settled?

Ans. CAPEx work is settled on a WBS element. The WBS element has the necessary budget allocated. It is created by Finance department.

4. What is refurbishment process?

Ans. You can read about refurbishment process here.

5. How refurbishment process is different from other business processes?

Ans. Here you go:

- Refurbishment process is mapped with order type PM04.

- Refurbishment order is created with reference to a material (not equipment).

- Cost of refurbishment is settled on a material (not cost center or WBS element).

- We need to activate split valuation in Material master and add value category in material master accounting view.

- It updates the moving average price of the material (Refurbished) after settlement.

- Refurbishment order can be created by t code IW81 also.

6. How breakdown maintenance and corrective maintenance are different from each other?

Ans. Here are the key difference between breakdown and corrective maintenance:

- In case of breakdown maintenance the technical object fails to start and becomes unproductive. On the other hand in case of corrective maintenance the technical object remains operational but not with its full capacity/ efficiency.

- Malfunction start/ ends date and time are recorded for breakdown but same are not applicable for corrective maintenance

- A fixing a minor leakage in a pipe by tightening the pipe or welding the pipe is an example of corrective maintenance. On the other hand if winding of a motor burnt off due to overload and motor fails to start then it is an example of Breakdown maintenance.

7. What configuration in SAP MM module required to be activated for refurbishment order?

Ans. We need to activate split valuation in SAP MM. We need to create valuation type and assign them to a value category. That value category is assigned to the material master in accounting view.

8. Which business process cover the maintenance of labortory equipments which are used to measure various quality parameters of incoming material and outgoing material for sale?

Ans. Calibration process covers the maintenance of laboratory machines. Laboratory machines needs to be recalibrate periodically. Over a period of time the laboratory equipment start giving incorrect values therefore they need re-calibration. There should be a separate order type to track the history and costing. Generally companies take help from a vendor to re-calibrate the machines.

If we do not do it then quality checks at the various stages of supply chain may go wrong.

9. What is Capital Expenditure (CapEx) process?

Ans. Let us understand basics of CapEx in below points:

- Capital Expenditure process includes the erection, commissioning and installation of new machines, sections, production lines or part of production line.

- The purpose of this installation is to increase (or upgrade) the efficiency, production, improvement in production and ensure that environment health and safety (EHS) are not impacted and pollution is reduced.

- Such kind of work is done a bigger scale and needs a separate budget.

- Finance department needs a proper justification to approve budget for it.

- Once Finance department is convinced with the return on investment they will create a WBS element and add budget on it.

- Execution of CapEx work is done by external vendor.

- In house maintenance department gets fully involved into it because post installation maintenance department has to take care of the new machine.

- Production department also immersed in this work because they have to ensure that all the new machinery works in its best efficiency.

10. What are the new business processes introduced in Asset Management SAP S4 HANA best practices?

Ans. The business processes in Asset Management as per best practices as follows:

- Corrective maintenance (BH1)

- Emergency maintenance (BH2)

- Preventive maintenance (BJ2)

- Reactive maintenance (4HH) (New)

- Proactive maintenance (4HI) (New)

- Operational and Overhead maintenance(4WM) (New)

- Improvement maintenance (4VT) (New)

- Maintenance resource scheduling (43R) (New)

11. What is Reactive maintenance ?

Ans. When there is a malfunction or abnormal situation with a machine in the manufacturing area then maintenance department is expected to react or respond on it. A maintenance request is created and accepted by an authorized person. Afterwards, planning and execution is done. It is a new name of emergency or breakdown maintenance.

12. What are Operational and Overhead maintenance processes?

Ans. Let us discuss both processes one by one:

Operation maintenance

- In the manufacturing area or production area sometime operations department needs services from maintenance department such as extra lighting, industrial extension boards, welding work, etc.

- This work falls under operational maintenance where maintenance department supports operations department in their daily routine work.

- It is not core job of maintenance department but needs documentation for cost and history tracking.

Overhead maintenance

- Overhead maintenance work is the work which falls on maintenance department from other maintenance departments

- For example: Mechanical department is doing maintenance of a pump and they want electrical department to deenergize the motor coupled with the pump, Civil department is working on a steel structure and they want welding work to be done by mechanical department

- This is also not the core job of the particular department but needs to be tracked, time booking should be done for this work

Both Operational and Overhead maintenance impact the core job and man power planning of maintenance department. Therefore it must be documented in system

13. Which maintenance process needs split valuation to be activated in SAP MM?

Ans. It is refurbishment process which needs split valuation to be activated in SAP MM SPRO.

14. Which t code is used to do usage decision on inspection lot triggered from calibration order?

Ans. QA32

15. What is improvement maintenance process in SAP S4 HANA best practices?

Ans. Improvement maintenance is similar to CAPEx process. In this process we can do erection, commissioning, construction work in plant area. Purpose of this work is to improvise the production process. You can read the question about CAPEx. Purpose is same. SAP has come up with a new name because many countries does not understand the word CAPEx.

Scheduling Parameters in SAP PM (10 Interview Questions)

Scheduling parameters are important in a maintenance plan and they have a very pivotal role to play in preventive maintenance order call dates

1. What are scheduling parameters in SAP PM?

Ans. Scheduling parameters in SAP PM are used in maintenance plans. They are mainly used to control the the date on which a maintenance order will be create automatically from a maintenance plan. There are thirteen scheduling parameters available in SAP PM.

2. Name all scheduling parameters in SAP PM.

Ans. Here is the list of scheduling parameters in SAP PM.

| S. No. | Scheduling Parameter Name | Where-used |

|---|---|---|

| 1 | Scheduling Indicator | Single Cycle and Strategy Plan |

| 2 | Shift Factor | Single Cycle and Strategy Plan |

| 3 | Tolerance | Single Cycle and Strategy Plan |

| 4 | Call Horizon | Single Cycle and Strategy Plan |

| 5 | Scheduling Period | All Plans |

| 6 | Completion Requirement | All Plans |

| 7 | Link type | Multiple Counter Plan |

| 8 | Maintenance Package Hierarchy | Strategy Plan |

| 9 | Offset | Single cycle plan and Strategy Plan |

| 10 | Cycle modification factor | All Plans |

| 11 | Lead float days | Multiple counter plan |

| 12 | Start date | All Plans |

| 13 | Factory Calendar | Single cycle, strategy plan |

3. Suppose I have two counters in a multiple counter plan. One is 1000 kms and another is 2000 running hours. If I want to trigger a maintenance order when both criteria are full fill or if any one of the criteria full fills. Do I need to make an enhancement in system or there is an SAP standard setting to achieve this?

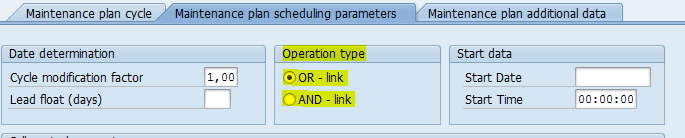

Ans. There is an standard facility in Multiple counter plan where we can assign two counters and put the condition whether we want both conditions to satisfy or any one condition to satisfy to trigger the maintenance order. To check this facility you have to run t code IP43. Then enter desired information and go to tab “Maintenance Plan Scheduling Parameters“. Under this tab there is a box with title “Operation Type“, here we have two radio buttons ‘AND’ & ‘OR’. Please refer below screenshot:

- If we select radio button ‘OR‘, it means that any of the counters cross the threshold value the maintenance order will trigger from Multiple Counter plan.

- If we select radio button ‘AND‘, it means that both counters must cross the threshold value to trigger the maintenance order

Please note that above concept is applicable only in Multiple Counter Plans.

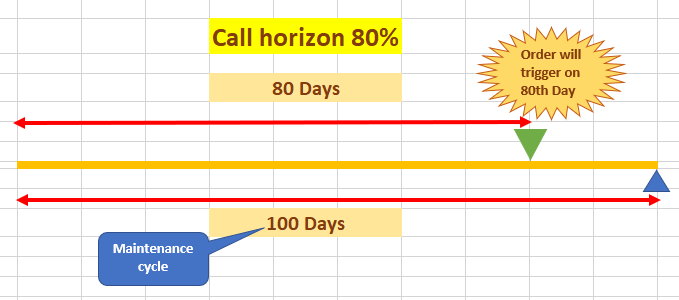

4. What is call horizon? Explain with example.

Ans. In this question do not go with definition of ‘Call horizon’. Definition will not give correct picture. Give answer in this way :-

Call horizon is a scheduling parameter. It is assigned in maintenance plan header. It decides the maintenance order call date. If the maintenance cycle is 100 days and call horizon is 100% then maintenance order will be triggered on 100th day. If call horizon is 80% then maintenance order will be triggered on 80th day.

Please refer below picture for understanding.

5. Why call horizon is important from business point of view?

Ans. Following points make call horizon important for maintenance department:

- Call horizon enables the feature to trigger maintenance call object in advance

- Advance trigger helps business do necessary arrangements involve plannig the internal manpower, contractor manpower and materials.

- Business can initiate the purchase of critical spare parts.

- Issue the material from warehouse and shift the material to site.

- Business gets advance info about upcoming maintenance activity in their pending list of orders.

6. If I want to trigger a maintenance order from a maintenance plan on every 7th day of a month, then what settings will I do in the maintenance plan other than a maintenance cycle of 1 month?

Ans. There is a feature “Scheduling Indicator” in scheduling parameters in maintenance plan. There are three options provided. Choose second option “Time – Key date“. This feature enable you to trigger order for a specific date.

7. What will happen if we make call horizon blank (or zero) and schedule the maintenance plan?

Ans. If we make call horizon as blank or zero and run the program to schedule the maintenance plan then maintenance order will be triggered immediately. In an implementation project you must be careful while putting a value in call horizon because if this field is blank for 5000 maintenance plans and all are scheduled on Go live date then 5000 maintenance orders will be triggered and all the reports will start showing those orders. This will result into a kiosk. Therefore, always recommend some value in call horizon.

8. If you want to trigger a maintenance order or notification on every Monday of the week. Which scheduling paramter will you use to achieve this?

Ans. We will select the start data in such a way that the order or notification triggers on every Monday. Maintenance cycle will be 7 days. It is advised here to see the future calls in IP10 for the plan so that you can verify that all future calls are falling on a Monday. Do not do the mistake of recommending “Scheduling Indicator” here.

9. If you want to trigger one maintenance order in each shift in one day. For example, First order at 0630 Hrs, second at 1430 hrs and third at 2330 Hrs. Which scheduling paramter will you use in such situation?

Ans. There is no scheduling parameter which can help you in such business requirement. But there is an alternative solution. You can put those maintenance plans (with maintenance cycle 1 day) in IP30H or IP30 and schedule them in three separate background jobs. First background job will run at 0625 Hrs, seconf will run at 1430 Hrs and thrid will run at 2325 hrs. So you will get all the maintenance orders triggered at the time they are required.

10. Suppose a factory runs only nine months in a year. Due to heavy snowfall it remains closed for three months. The maintenanc department wants to do the time based maintenance say once in 6 months. Now during these six months three months factory was closed then how will you map the scenario to calculate correct maintenance cycle of six months when three months factory was closed? What will be your recommendation to client?

Ans. We can recommend to use radio button -> scheduling indicator as Time – Factory Calendar. This will activate factory calendar and maintenance calls will be generated as per factory calendar which will have only nine months as working days. This factory calendar is created by production people in t code SCAL.

Notification in SAP PM (7 Interview questions)

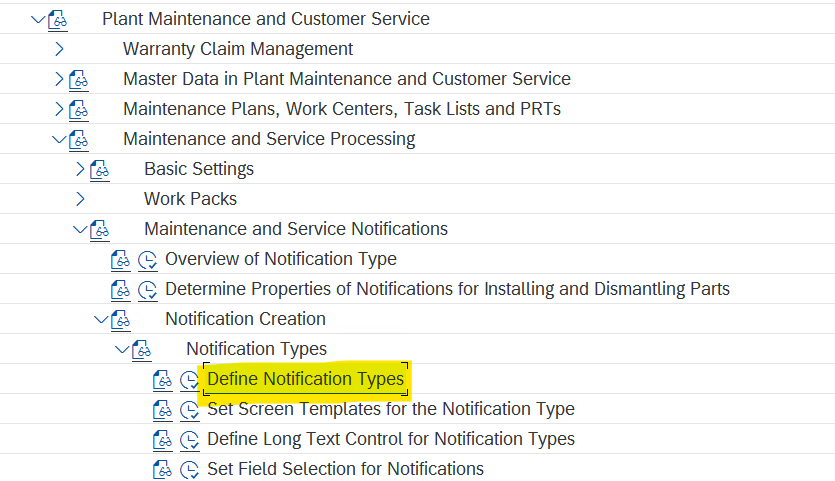

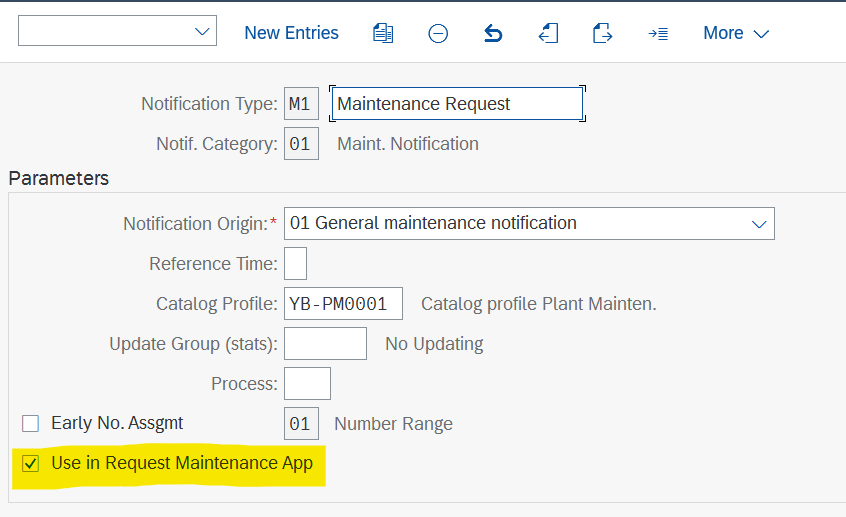

1. You want to create a new maintenance request using Fiori app “Request Maintenance”. When you launch the fiori app you do not see any notification type appearing in the drop down list. What will you check in the system to make the drop down list appear.

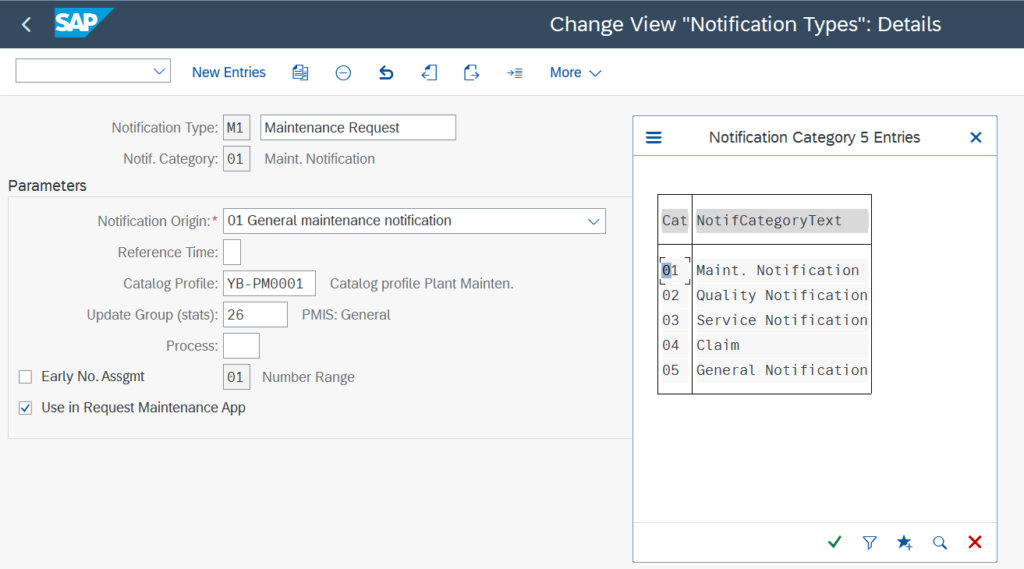

Ans. This can be achieved by setting a check box in “Use in request in Maintenance App” in configuration (SPRO). Please refer below path.

Configuration path: Plant Maintenance and Customer Service -> Maintenance and Service Processing -> Maintenance and Service Notifications -> Notification Creation -> Notification types -> Define Notification types

2. You have created a new notification type in configuration (SPRO). You have created few notifications but these notification’s count is not appearig in the PMIS reports such as MCI1, MCI2, MCI3 and so on. What could be the reason of this?

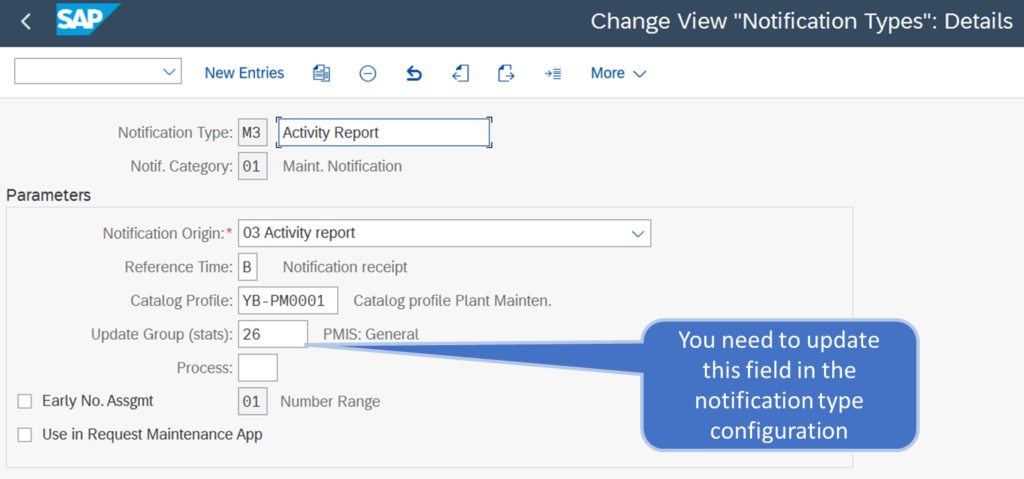

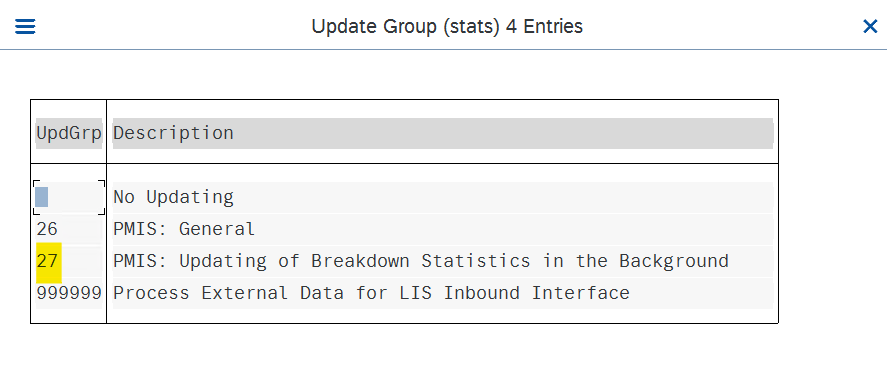

Ans. While configuring the new notification type there is a setting for notification type. You need to maintain value 26 to update all PMIS reports. Please refer below screenshot

If you want to update the breakdown related statistics then update this field as 27- PMIS-Updating of breakdown statistics in the background.

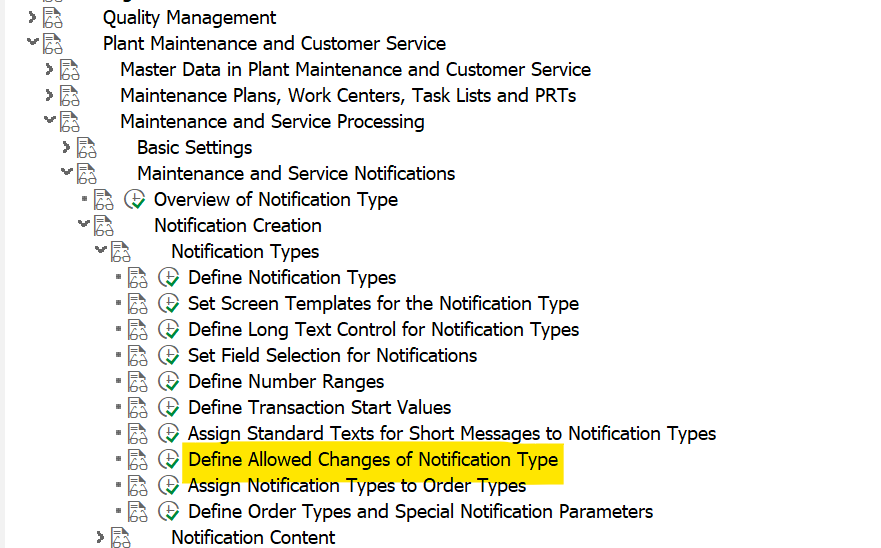

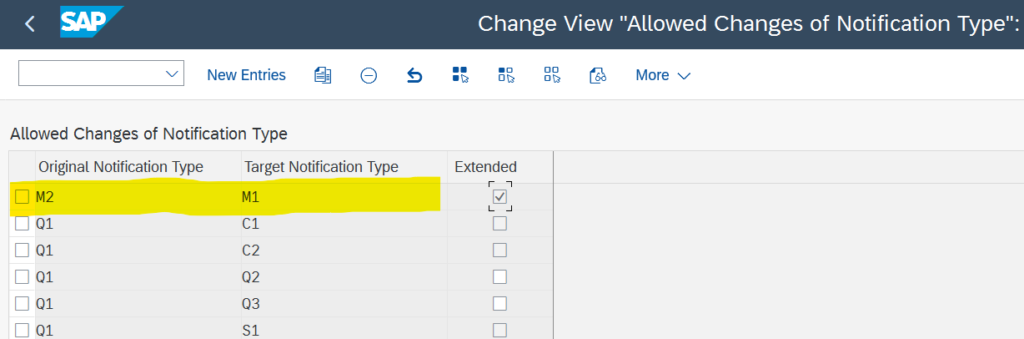

3. There is a normal maintenance (M1) required in the plant area but production department has created a malfunction report (M2). Is it possible to change the notification type after creation?

Ans. Yes, it is possible to change the notificaton type. We have to do following settings in system:

- Activate business function: You need to activate a business function LOG_EAM_SIMPLICITY_5 to allow change of notification type in WEB UI and business function LOG_EAM_CI_7 to allow the same using t code IW21, IW22.

- Configuration setting: In SPRO there is node toi define the origin and target notification types.

4. What is notification category? What is its main function?

Ans. Notification category decides whether a notification is created for PM or QM or CS module (Application component). In standard SAP there are five notification categories:

| Category | Notification Catrgory text |

|---|---|

| 01 | Maintenance notification |

| 02 | Quality notification |

| 03 | Service notification |

| 04 | Claim |

| 05 | General notification |

As per the notification category the notification type appears in the dropdown list of while creating notifications. For ex: If we create notification with category 01 then it will appear in drop down values of notification in tcode IW21. It will not be visible in IW51 and QM01.

5. What are the standard SAP notification types available in system for PM module?

Ans. In standard SAP we have five notification types available in S4 HANA system:

| Notification type | Notification Description |

|---|---|

| M1 | Maintenance Request |

| M2 | Malfunction report |

| M3 | Activity report |

| Y1 | Reactive work (Newly added in S4 HANA) |

| Y2 | Proactive work (Newly added in S4 HANA) |

6. What are different ways to create a maintenance notification in SAP?

Ans. There are seven ways to create a maintenance notification:

- Tcode IW21: We can create a maintenance notification by using tcode IW21.

- Tcode IQS1: We can create any type of notification (including maintenance notification) using tcode IQS1.

- Maintenance Plan: We can trigger a maintenance notification thru the maintenance plan. We have to set notification as maintenance plan category in the initial screen of maintenance plan creation.

- From a maintenance order: In the IW31/32 tcode we can create a maintenane notification from the maintenance order main screen.

- Request maintenance Fiori App: We can create a maintenance notification from the Fiori app “Request maintenance”.

- Create maintenance request Fiori App: We can create a maintenance notification (default notification type Y1) using Fiori app “Create maintenance request”.

- Notification triggering from measurement document: In a measuring point if the measuring reading goes beyond upper or lower limit then a notification can be triggered to address the issue. But this feature is available only in S4HANA Public Cloud. In on-premise and private cloud it will be an enhancement.

7. What is special in a notification for breakdown process?

Ans. Here you go:

- For breakdown maintenance we use M2 notification type.

- It has malfunction start/end date and time.

- There is a breakdown indicator which hekps to calculate breakdown duration (in hours)

- Malfunction start/ end date and time helps in updating MTBR and MTTR report

Maintenance Order in SAP PM (15 Interview Questions)

1. What is the purpose of Final issue indicator in maintenance order reservation and while posting confirmation?

Ans. Understand the functionality in below bullet points:

- When you add a component in a maintenance order with quantity reservation get created automatically. If you set the final issue indicator then reservation items will not appear in MIGO. It indicates that no more spare parts are required.

- If the quantity of material is 10 EA and you have posted partial GI (say 5 EA quantity) in MIGO. Afterwards if you set the final issue indicator in maintenance order-> component tab -> General Data or while posting time confirmation, then system will not stop goods issue for remaining quantity.

- Both above points are applicable for manual reservation also (using t code MB21 or using “Create Reservation” Fiori App)

- This is question is important when you are facing your client or job interview.

2. Which movement type is used to post goods movement against reservation triggered from maintenance order? Is it possible to change it?

Ans. Movement type 261 is used to post goods against reservation triggered from maintenance order. Yes, it is possible to create a custom movement but it is not recommended to do that.

3. Is it possible to assign a user status to the operation and sub operation of a maintenance order?

Ans. It is possible to assign user status to the operation of a maintenance order but not to sub-operation.

4. How to settle maintenance cost at order operation level?

Ans. We have to activate a Business function LOG_EAM_OLC in ECC. This is an in-built feature in S4 HANA. Operation Level Costing can be activated per Order Type and Plant in SPRO. Follow this path in SPRO:

Plant Maintenance and Customer Service – Maintenance and Service Orders – Functions and Setting for Order Types – Costs at Operation Level

It means that you can activate and deactivate this feature at plant and order type level. To see the operation level cost you have to go to top menu bar and select option Extra → Cost Reports → Operation costs overview

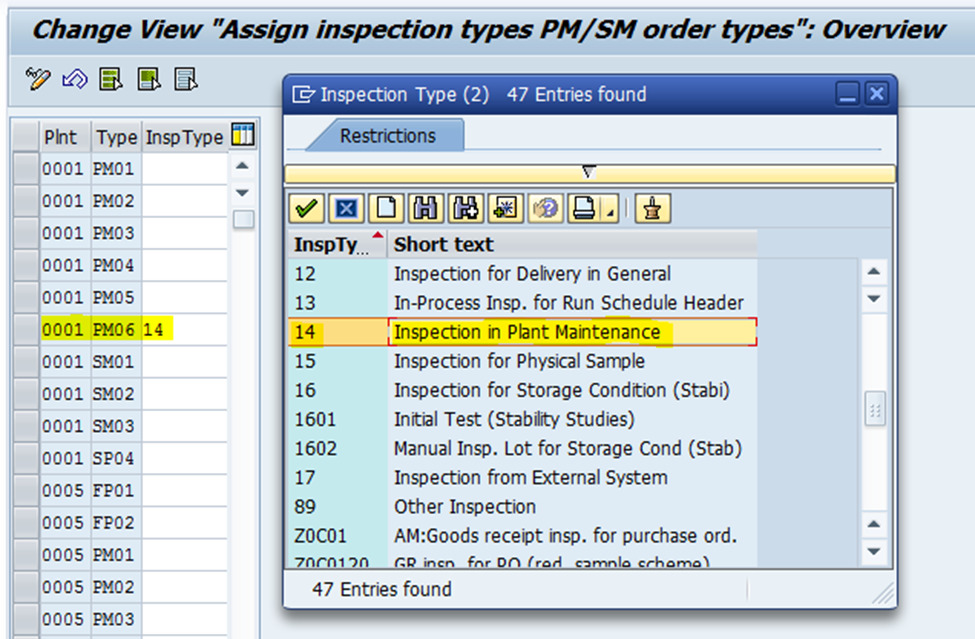

5. Which configuration setting will you check when inspection lot is not triggered from a maintenance order on scheduling a Calibration Plan ?

Ans. There are three main configuration settings which needs attention when an inspection lot does not triggered from a maintenance order:

- Inspection type – 14

- Assignment of inspection type 14 to PM order type (PM05)

- Inspection point setting in QM must not be disturbed.

6. Which order type you use for refurbishment?

Ans. As per standard SAP settings PM04 is used for refurbishment order.

7. Which t code is used to create refurbishment process?

Ans. IW31 and IW81. This questions can be asked and interviewer expects you to answer both t codes.

8. Is it a rule that you will use PM04 order type for refurbishment? Can you configure another order type for refurbishment?

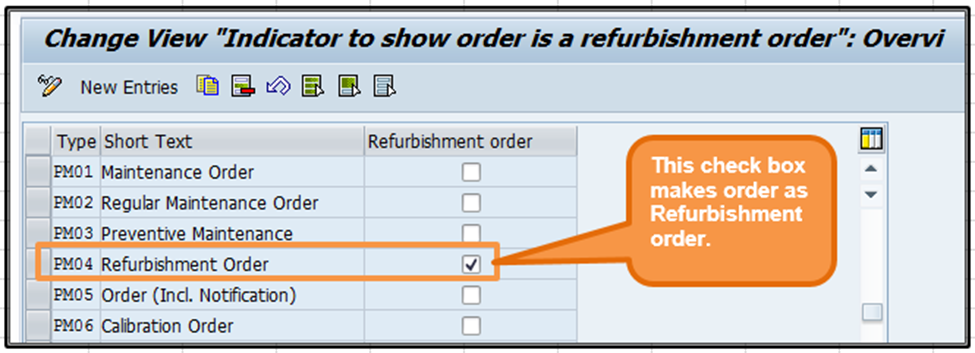

Ans. There is no rule as such. You can configure any order type for refurbishment. There is a configuration setting in SPRO. Please check below path in SPRO.

Plant Maintenance and Customer Service ⇒ Maintenance and Service Processing ⇒ Maintenance and Service Orders ⇒ Functions and Settings for Order Types ⇒ Indicate Order Type for Refurbishment Processing[/success]Plant Maintenance and Customer Service ⇒ Maintenance and Service Processing ⇒ Maintenance and Service Orders ⇒ Functions and Settings for Order Types ⇒ Indicate Order Type for Refurbishment Processing

Once this indicator is set for any order type, the order will be created with reference to material (not equipment).

9. What is purpose of maintenance activity type in maintenance order?

A. Purpose of maintenance activity type is to further classify(or categorize) the maintenance process according to type of maintenance business. For ex: Cleaning, Lubrication, Pre Shutdown activities, Inspection, Repairing, Rework, Shutdown etc.

- It is placed at the header of maintenance order. MAT is a 3 Character key. It is recommended to use numbers here so that you can have them from 000 to 999.

- In configuration we can define it and assigned to maintenance order types so that only relevant Maintenance Activity type appears on the maintenance order screen.

It is used in various standard reports to track and analyze maintenance incidents and cost based on Maint. Activity Type. For ex: IW38/39, MCI8.

In these reports business can analyze how much budget has been utilized in Inspection, Repairing, Rework or shutdown etc. So design maintenance activity type in such a way that it helps in good quality reporting.

Important configuration settings related to maintenance activity type in SAP PM is here:

Plant Maintenance ⇒ Maintenance and Service Processing ⇒ Maintenance and Service Orders ⇒ Functions and Settings for Order Types ⇒ Maintenance Activity Type ⇒ Define Maintenance Activity Type

Plant Maintenance ⇒ Maintenance and Service Processing ⇒ Maintenance and Service Orders ⇒ Functions and Settings for Order Types ⇒ Maintenance Activity Type ⇒ Assign valid Maintenance Activity Types to Maintenance Orders

Plant Maintenance ⇒ Maintenance and Service Processing ⇒ Maintenance and Service Orders ⇒ Functions and Settings for Order Types ⇒ Maintenance Activity Type ⇒ Default values for Maintenance Activity Type for each Order Types

10. Why does settlement of a maintenance order is important?

Ans. Settlement of a maintenance order is important because if we will not settle the cost on a valid receiver such as cost center, internal order, WBS element etc then cost will remain on the maintenance order and not reflect in management reporting. Management reporting is important for profitability analysis.

11. Which configuration setting allow a Calibration order to trigger an inspection lot from maintenance order?

Ans. There is a setting related to assigning inspection type 14 to maintenance order type. Please follow below configuration path in SPRO:

Plant Maintenance and Customer Services ⇒ Maintenance and Service Processing ⇒ Maintenance and Service Orders ⇒ Functions and Settings for Order Types ⇒ Assign Inspection Types to Maintenance/ Service Order Types

Please check below screen shot from configuration SPRO:

If this configuration is not maintained then you cannot trigger inspection lot from a Calibration Order. In general we use order PM06 as Calibration Order.

12. What are the possible settlement cost receivers in maintenance order?

Ans. For the Maintenance there are number of settlement (or cost) receivers but only few are relevant in practical scenario.

Here is the list of relevant settlement receivers:

- Cost Center

- WBS Element

- Material

- Order

- Fixed Asset

If you want to see the complete list of settlement receivers then go to below path in configuration (SPRO):

Plant Maintenance and Customer Services ⇒ Maintenance and Service Processing ⇒ Basic Settings ⇒ General Order Settlement ⇒ Maintain Settlement Profiles

Select Settlement Profile “40” to see the complete list.

13. What are the possible ways we can create a maintenance order in SAP PM?

Ans. There are 8 ways to create a maintenance order in SAP PM Module

- T code IW31: You can create a maintenance order using t code IW31. This is to most common method to create a maintenance order

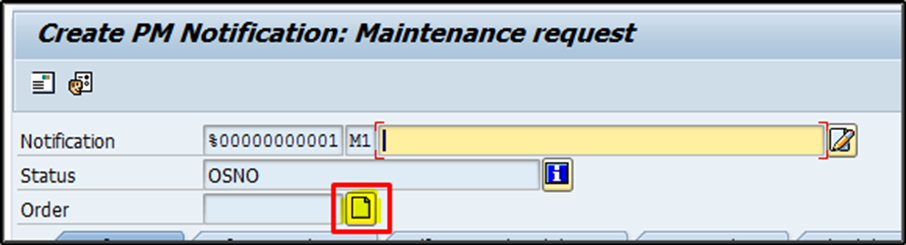

- From Maintenance Notification: You can create a maintenance order through a notification. There is a separate button provide with white sheet. Please refer below screenshot:

- T code IW34: You can create maintenance order with reference to a notification using t code IW34. I request you to run this t codes in SAP and check out the initial screen. Generally end user does not use this but for interview purpose you should know it.

- T code IW81: You can create refurbishment order using this t code. No other order can be created using this t code.

- Scheduling of Maintenance Plan: When you schedule a maintenance using IP10 or IP30 t code system triggers a maintenance order as per the schedule. Here maintenance order is triggered automatically.

- T code IW28: IW28 displays list of notifications in change mode. At the top application tool bar there is an option to create maintenance order. You will have to select the notification and click on create order white sheet. This will redirect you to t code IW34 screen. Try this.

- Fiori App -> Manage Maintenance Notifications and Orders: Using this FIori app user can create maintenance order from the maintenance notification. Orders can be created at mass level also.

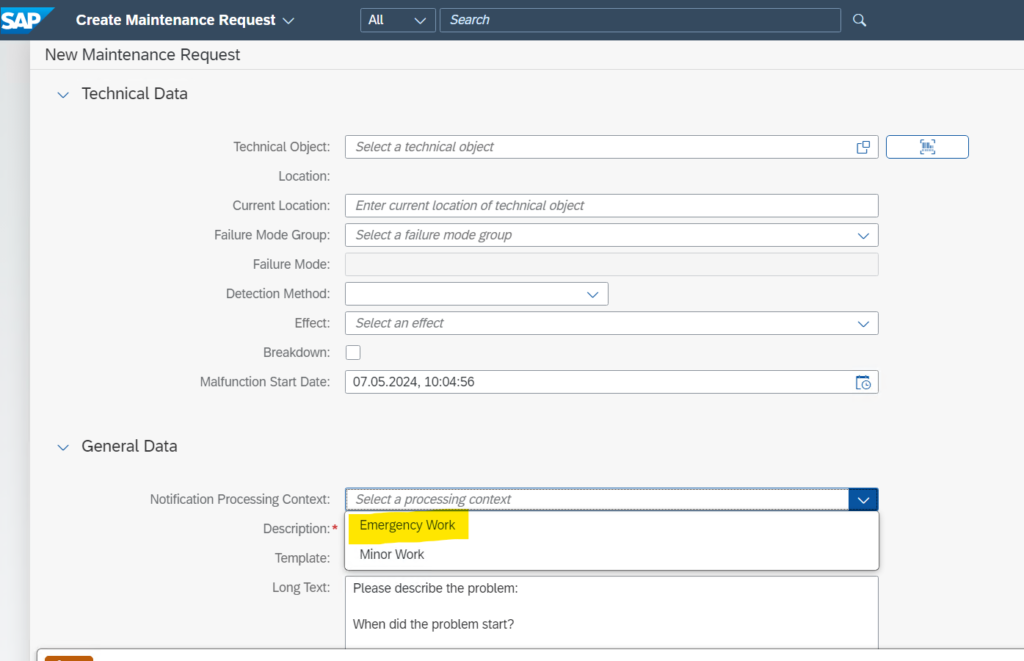

- Fiori App -> Create maintenance request: Using this Fiori app user can create a maintenance notification (Y1) and trigger a reactive maintenance order automatically but notification processing context must be selected as “01-Emergency work“.

14. What is difference between IP30 and IP30H to schedule maintenance plans at mass level to trigger maintenance order or notification? Both tcodes do the same thing then how are they different?

Ans. IP30 and IP30H are different tcodes with same outcome but their technical design is different. Here is the diference:

- IP30H was first available in SAP ECC EHP7 (Enhancement pack 7) and IP30 was already available since SAP 4.7 version.

- IP30 is known as Deadline monitoring but IP30H is known as Mass schedule maintenance plans.

- IP30 tcode has very limited fields on selection screen to cover maintenance plans. However, in S4 HANA IP30H has selection variables such as Planning Plant, Planner Group, Main Work Centre, FLOC & Equipment.

- IP30 process maintenance plans in a serial manner (one by one) which results into performance issues. On the other hand IP30H process the maintenance plans parallelly which results into fast processing of background job to trigger maintenance call object. We need to enter Server group for parallel processing and Number of parallel processes (max. value 10). Both values can be given by SAP Basis consultant.

- IP30 is an inbuilt feature and IP30H can be activated by using business function LOG_EAM_MPS1 in tcode SFW5. Basis consultant can help you to activate business function.

15. Is it possible to create a maintenance order from a maintenance notification automatically?

Ans. Yes, it is possible to create a maintenance order automatically from a maintenance notification. It is a new feature in S4 HANA. There is a fiori app “Create maintenance request“. In this Fiori app there is a field “Notification processing context“, if this field has value “01-Emergencey Work” then system will trigger maintenance order automatically from notification (Y1).

You need authorization of following objects:

- I_EXCP_MN

- I_EXCP_MO

Linear Asset Management in SAP PM (4 Interview Questions)

1. In what type of industries Linear Asset Management (LAM) is used?

Ans. Linear Asset Management (LAM) is used primarily in following industries:

- Rail-Road Industry

- Oil & Gas Industry managing Pipelines

- Utility Industry managing Transmissing and distribution lines

2. How to activate Linear Asset Management functionality in SAP?

Ans. There are two business functions need to be activated in SAP using tcode SFW5.

- LOG_EAM_LINEAR_1

- LOG_EAM_LINEAR_2

There is a pre-requisite to activate above business functions that is activation of two more business functions:

- LOG_EAM_CI_1

- LOG_EAM_SIMPLICITY

Once above business functions are activated LAM is activated and LAM related nodes start appearing in SPRO and linear data start appearing in all plant maintenance master data and transaction data.

3. What are the functions activated on easy access screen for LAM?

Ans. Following changes happen in system after activation of LAM related business functions:

- New equipment and functional location category “L – Linear Asset” start appearing in system.

- A new view profile LAM01 is created in system where we can add Linear data (LAM related fields) with equipment and functional location

- Linear check box can be activated to make any category work for LAM

- Measuring point category will have Linear asset check box appearing in SPRO

- Define Offset types for Linear data

- In equipment and functional location data we can maintain length, offeset data, start and end point of linear asset

- Linear data will start appearing in all notifications, order, task list, maintenance plans, measuring point etc

4. What do you mean by LDC in Linear Asset Managment?

Ans. LDC stands for Linear Data Charactristics (LDC). It contains the important parameters of the linear assets (such as Pipeline, Railway track or Overhead elec line).

For ex: a Railway Track can have LDC such as Speed of Train, nearest railway station, distance between two tracks, A pipe line can have LDC such as Diameter of Pipeline, color code, pipe material etc

LDCs are captured as characteritics of the asset in master data.

SAP PM Integration with other modules (7 Interview Questions)

In this section there are SAP PM Interview questions related to integration of SAP PM module with other modules. These questions are important not only for interview perspective but also from client facing role also. So go through them carefully.

1. How SAP PM module is integrated with SAP MM module?

Ans. SAP PM is integrated with MM module in following ways

- Purchase requisition triggers from maintenance order for components (material) for item category ‘N’.

- Create reservation from maintenance order for components for item category ‘L’.

- Purchase requisition triggers from maintenance order for external services for Control key PM02 and PM03. category ‘N’.

- Post good issue in MIGO for reservation with movement type 261.

- Post Goods receipt in MIGO for PO with movement type 101.

- Create and accept a Service entry sheet for posting actuals of external services with t code ML81N.

- Material master with type ERSA for maintenance spare parts.

- Split valuation in material for refurbishment process

2. How PM module is integrated with PS module?

Ans. We use WBS element for budget allocation and cost settlement of maintenance in CAPEX and Annual Shutdown maintenance.

WBS element can be created in CJ20N t code by PS consultant. It is then approved by authorized person in maintenance and Finance department. Finance department allocates the budget in it. During postings of actuals such as GI, GR, Completion confirmation the budget is consumed. System gives warning or error message if budget is consumed 90% or 100% (depends on settings). At that time maintenance department can ask Finance department to increase the budget in WBS element.

3. How PM module is integrated with FI module?

Ans. Please check following points for integration with FI:

- Assign the FI asset number in equipment master under organization tab.

- Integration of valuation class for spare parts with GL account.

- Integration of material groups with GL account for purchase without material codes.

4. How PM module is integrated with CO module?

Ans. Here are the integration points between PM and CO module.

- Assign cost center in equipment and functional location and that cost center automatically copy to maintenance order and then in settlement profile of order and finally the cost of maintenance settles on the cost center.

- Assign cost center in work center costing tab and this cost center automatically copy into order as Responsible cost center.

- Activity type is used to capture the internal man power hourly rates. It is created and assigned to Cost center. That cost center is assigned to main work center under costing tab. During maintenance processing the activity type automatically copy to maintenance order operation.

- Settlement profile is configured in SPRO to define cost receiver.

- Define value category in SPRO and assign the cost elements to capture the break up of cost such as Spare parts consumption, internal man power, external man power etc.

- Assign cost elements to maintenance cost key figures. This helps to display breakup of cost figures in standard SAP report such as MCI4, MCI8

5. How PM module is integrated with QM module?

A. Remember below points

- Add inspection point in task list for calibration process

- Assign inspection type = 14 to order type to trigger inspection lot from maintenance lot in calibration process

- Enter usage decision in QA32 for inspection lot triggered from calibration order

- Configure separate order type (PM05) for calibration process.

6. How PM module is integrated with EHS module?

7. What is the t code to create Activity type? Who create activity type?

Ans. KP26 is the t code to create Activity type. Generally CO consultant creates the activity type. However, plant maintenance consultant should also know the process to create the activity type.

In Fori there is a very good app -> Manage Activity Type. This app can also help user to create and manage rates for internal man power.